0086 18049845758

GOLDEN PAPER

GOLDEN PAPER

GOLDEN PAPER

GOLDEN PAPER

Are you struggling to find a safe and durable material for liquid packaging in today’s competitive market? If so, consider Liquid Packaging Board (LPB) as a new option. In this article, we’ll explore what LPB is, its advantages, and its applications to help you make an informed decision.

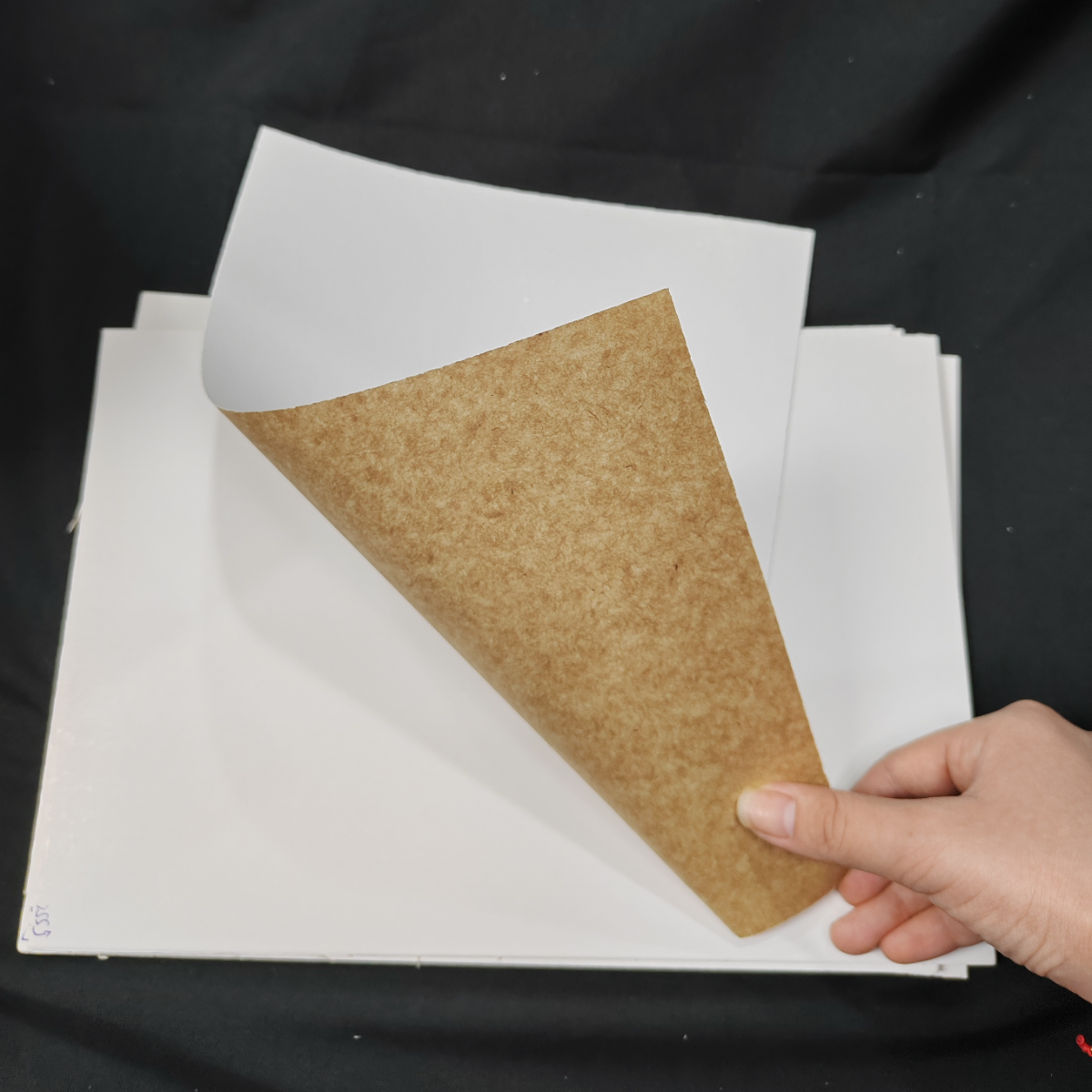

Liquid Packaging Board (LPB) is a specialized paperboard used for aseptic packaging of beverages like dairy products and fruit juices. It consists of three layers: a top layer, a middle core, and a bottom layer, all coated for enhanced performance. Unlike regular liquid packaging board, Kraft Back LPB (also known as CKB, or Kraft-Backed Liquid Packaging Board) uses unbleached natural pulp for its base layer, making it a more sustainable choice.

Since LPB with Kraft Back is made with unbleached natural pulp, it is a more environmentally friendly option. The unbleached process reduces the need for chemicals in production. At Golden Paper, we ensure that our LPB with Kraft Back not only meets sustainability standards but also complies with strict food safety regulations.

The use of natural long fibers enhances the physical strength of LPB with Kraft Back . The strong fiber bonding gives it excellent folding endurance and resistance, ensuring that the packaging remains intact throughout filling, transportation, and storage—even under pressure from liquid weight and external forces.

LPB with Kraft Back features a triple-coated, single-sided surface using premium imported coatings. This results in a smooth and even texture, stable color performance, and enhanced printability. The uniform coating allows for sharp and vibrant full-tone and halftone printing, making it ideal for high-quality branding and packaging design.

This material is water-resistant, light-resistant, and highly durable against fading, making it perfect for long-term storage. It also has excellent lamination bonding, water resistance, and edge wicking resistance, ensuring optimal performance in liquid packaging applications.

Since LPB with Kraft Back uses unbleached pulp, it reduces chemical usage and lowers production costs. Additionally, its higher bulk allows for lower basis weight options to replace heavier white-backed LPB, helping you cut down material costs while maintaining high performance.

LPB with Kraft Back is widely used for packaging milk, yogurt, and other dairy-based liquids, ensuring freshness and safety. It is also ideal for juices, fruit teas, and other beverages, offering essential sealability and protection. Moreover, due to its high moisture resistance, anti-leak properties, and tear strength, LPB with Kraft Back is suitable for frozen and refrigerated food packaging as well.

LPB with Kraft Back is a safe, eco-friendly, and cost-effective packaging solution that meets the demands of the food industry. If you are looking for a reliable liquid packaging material, feel free to contact us at Golden Paper. Our team is ready to help you find the perfect solution for your needs!