0086 18049845758

GOLDEN PAPER

GOLDEN PAPER

GOLDEN PAPER

GOLDEN PAPER

In situations where paper-based data needs to be shared widely, carbonless copy paper is commonly used across various industries. However, traditional carbon paper often suffers from fading and is easy to counterfeit, which affects the clarity and security of important documents. So, why not choose carbonless copy paper? In this article, I’ll explain what carbonless paper is and provide more details about it. Keep reading if you're interested!

Traditional carbon paper works because it has a carbon-coated layer, also known as carbon film, between sheets of paper. When pressure is applied, the carbon is transferred to the sheet below, creating a copy. In contrast, carbonless copy paper is made without any carbon materials, which is why it’s called 'carbonless. You can call it NCR paper, which means no carbon required.

Unlike traditional carbon paper, carbonless copy paper is made up of three sheets: the top sheet, middle sheet, and bottom sheet. These are called CB (coated back), CFB (coated front and back), and CF (coated front). The back of the CB sheet is coated with microcapsules of ink, while the front and back of the CFB sheet are coated with a reactive clay layer, and the back is also coated with microcapsules of ink.

When you apply pressure to the top sheet, the microcapsules on the back of the top sheet release a carrier oil with a color-forming agent, which reacts with the color-sensitive layer on the middle and bottom sheets, causing the writing to appear on all three sheets. That’s why when you write on the top sheet, the same text appears on the middle and bottom sheets.

Carbonless copy paper is widely used across various industries. Below, I’ll list some of its more common uses. If you’re a distributor, you might want to consider getting involved with these industries.

Businesses often use carbonless paper to create two or three copies of invoices, receipts, and purchase orders. This ensures that both the customer and the business have a record of the transaction.

Carbonless copy paper is commonly used for forms and applications that require multiple copies, such as contracts, work orders, and delivery notes. This makes it easier to distribute copies to different parties.

Legal professionals can use carbonless copy paper to create copies of agreements, contracts, and other legal documents that need to be signed and distributed to multiple parties.

In healthcare settings, carbonless copy paper is used for medical forms such as patient records, prescription slips, and other documents that need multiple copies to be recorded and shared with different departments or healthcare providers.

Carbonless copy paper is sometimes used for event tickets, with one copy kept by the attendee and another by the event organizer.

In logistics and transportation, carbonless copy paper is used for bills of lading, delivery notes, and other documents that need multiple copies for the shipper, receiver, and carrier.

Traditional carbon paper uses carbon powder or carbon sheets, which can make your hands and documents dirty while writing. In contrast, carbonless copy paper uses a chemical coating to create copies, eliminating the need for carbon powder. This makes it cleaner, tidier, and more environmentally friendly.

Carbonless copy paper can generate multiple copies at once without the need to insert carbon paper manually, helping you work more efficiently. It's an excellent choice when you need to quickly record and copy information.

Carbonless copy paper uses pressure to trigger a chemical reaction, making the copied text clear and stable. This ensures that the copies are readable and suitable for long-term storage.

Carbonless copy paper can be used for both handwritten and printed documents, offering strong compatibility. As I mentioned earlier, carbonless paper is versatile and can be used in a variety of situations.

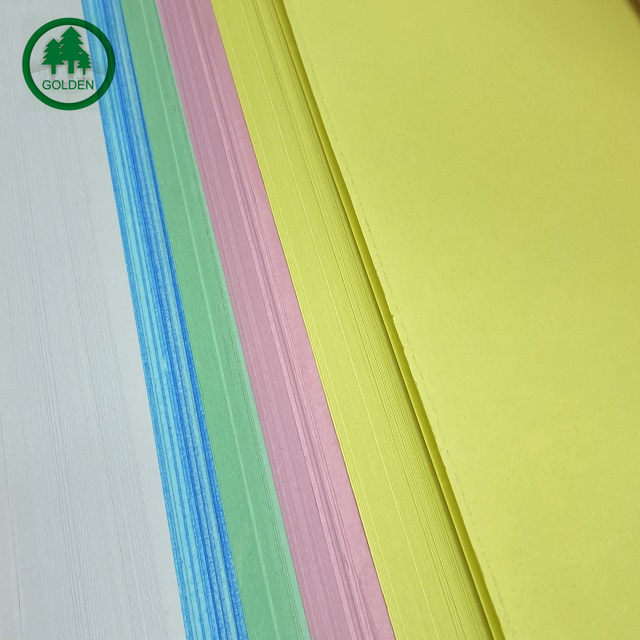

Once you have carbonless copy paper, how can you identify its type? Generally, the top sheet is white, while the middle and bottom sheets are commonly colored red, blue, green, or yellow. The top and bottom sheets are thicker, while the middle sheet is thinner. In addition to judging by thickness, you can also analyze the edge color of the paper. Only the middle sheet contains both the color-forming agent and the color-sensitive agent. When the paper is cut, the microcapsules on the back of the middle sheet are broken and react with the color agent on the front, which causes the edges of the middle sheet to appear blue-black. The edges of the top and bottom sheets, however, remain clean.

As a strong and reliable paper supplier, Golden Paper can provide you with high-quality carbonless copy paper and other paper products that suit your business needs, helping your business grow and succeed. By choosing Golden Paper, you not only get premium products but also our professional knowledge and dedicated service. If you have any purchasing needs, feel free to contact us!